Overview

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

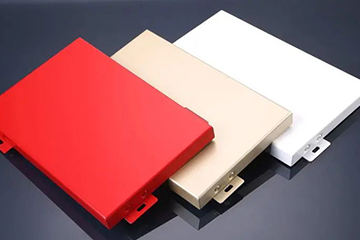

Product

Adhering to surpassing traditional ways of thinking and development models, taking a differentiated competitive route as the strategic starting point, and promoting the concept of innovative products through providing multiple creative methods, with a forward-looking perspective and the role of a promoter, we are committed to the advancement of China's metal building materials industry.

MORE +

Engineering

Following the high-quality development model of accumulation and gradual progress, our products have gained more and more excellent reputation in the market and industry.

MORE +

Marketing

Shanghai Jixiang Building Materials Group has always adhered to a flexible marketing strategy, actively carried out social centered marketing planning work, and implemented foreign sales strategies. Exporting to countries and regions such as Russia, Germany, Canada, the United States, India, Australia, etc., to meet high-end demand from various foreign countries.

MORE +

News

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

Sustainability

Through long-term social responsibility management and practice, Jixiang has consciously undertaken historical missions, fulfilled social responsibilities, and promoted sustainable development of the enterprise, gradually forming its own unique social responsibility management model - mission led social responsibility management.

MORE +

Contact

The world of auspiciousness, the auspiciousness of the world, Shanghai Jixiang Building Materials Group has the courage to assume social responsibility, become stronger and larger enterprises, and serve society with patriotism and love for the people.

MORE +

Aluminum coil series

Aluminum coil, to put it more colloquially, refers to the roll shape of aluminum material, which is a classification of aluminum plates, also known as aluminum coil plates. It is made of aluminum raw material that is rolled by a rolling mill, then trimmed and annealed. Due to different processing techniques, it is further divided into hot-rolled coils and cold-rolled coils.

Aluminum coils are made of different materials, roughly divided into pure aluminum coils and alloy aluminum coils. They have a wide range of uses, and aluminum coils are used for continuous punching molds, which are efficient and cost-effective for customers. Aluminum coils are often seen in fields such as electronic product processing, mechanical parts manufacturing, pipeline insulation engineering, and so on.

Our company uses high-quality aluminum foil as the substrate for color coated aluminum coils, introduces high-tech technology, cooperates with high-performance roller coating processing technology, and combines advanced production technology to effectively control the accuracy and flatness of the board, with uniform color and bright luster. The product has excellent processing performance, durability, acid resistance, alkali resistance, corrosion resistance, powdering resistance, decay resistance, UV radiation resistance, friction resistance, and other characteristics.

Product specification:

A. Thickness 0.036mm -0.60mm;

B. Width 1200mm -1500mm

Product colors: various colors

Table 1 Coating Appearance Quality

| Defect Name | Defect regulations | Permissible range | |

| Superior products | Qualified products | ||

| Corrugation | Not allow | Not obvious | |

| Tympanic bulla | ≤10mm | Not allow | No more than 1/m |

| Defect | ≤3mm | No more than 3/m | No more than 10/m |

| Scratches | Total length | Not allow | ≤100mm/m |

| Scratch | Total area | Not allow | ≤300mm/m |

| Chromatism | Not obvious | △E≤2 | △E≤2 |

Table 2 Physical and Mechanical Properties of Coated Aluminum Foil

| Project | Technical requirement | ||

| External wall panel | Inner wall panel | ||

| 涂層厚度(um) | ≥25 | ≥12 | |

| Glossiness deviation |

When the glossiness is ≤ 70, the error of the limit deviation is ≤ 10 When the glossiness is ≤ 70, the error of the limit deviation is ≤ 5 |

||

| Hardness | ≥HB | ||

| Adhesion, Grade | Not inferior to level 1 | ||

| Impact resistance | 50kg cm without peeling paint or cracking | ||

| Coating flexibility | ≤2 | ≤3 | |

| Boiling water resistance | No change after 2 hours | ||

| Chemical resistance stability | Dirt collection | ≤15% | / |

| Acid resistance | 2% HCL24h without change | ||

| Alkali | No change in 2% Na0H24h | ||

| Solvent resistance | 20 engine oil remains unchanged for 24 hours | ||

| Washability | ≥ 10000 times without change | ||

| Resistance to artificial climate aging | Chromatism | ≤3.0 | / |

| Loss of light level | Not inferior to level 2 | / | |

| Other aging properties | Level 0 | / | |

| Patience | Not inferior to level 2 | / | |

Jixiang Serve You

innovation driven

Building a Competitive Building Materials Group